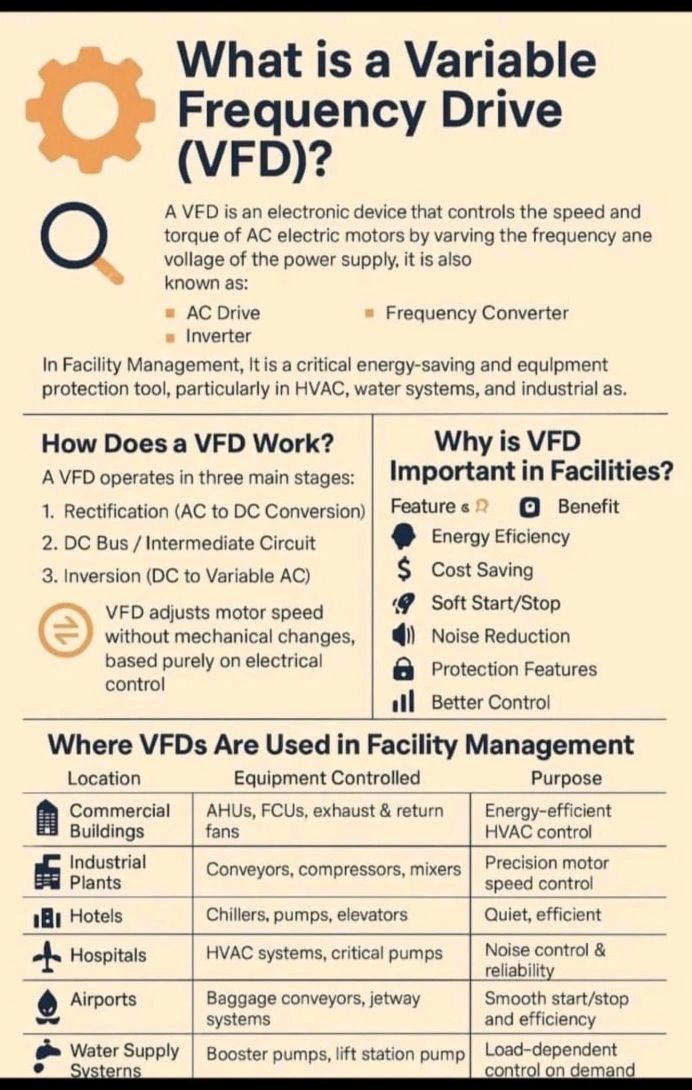

What is a Variable Frequency Drive (VFD)?

A Variable Frequency Drive (VFD) is an electronic device that controls the speed and torque of an AC motor by adjusting the frequency and voltage of the power supplied to the motor.

It is also known as Adjustable Speed Drive (ASD) or AC Drive.

🔹 How Does a VFD Work?

A VFD changes the power supplied to the motor in three stages:

1. Rectifier s

....

Read More

What is a Variable Frequency Drive (VFD)?

A Variable Frequency Drive (VFD) is an electronic device that controls the speed and torque of an AC motor by adjusting the frequency and voltage of the power supplied to the motor.

It is also known as Adjustable Speed Drive (ASD) or AC Drive.

🔹 How Does a VFD Work?

A VFD changes the power supplied to the motor in three stages:

1. Rectifier stage → Converts incoming AC power to DC.

2. DC Bus (filter stage) → Smoothens and stores energy in capacitors.

3. Inverter stage → Converts DC back to variable-frequency AC using IGBTs (Insulated Gate Bipolar Transistors).

👉 By controlling the frequency (Hz), the motor speed is adjusted (since motor speed ∝ frequency).

🔹 Why is a VFD Important in Facilities?

●Energy Savings: Reduces power consumption by running motors at required speeds instead of full speed.

●Process Control: Provides precise speed and torque control.

●Equipment Life Extension: Reduces mechanical stress on pumps, fans, and conveyors.

●Reduced Maintenance: Soft start/stop prevents wear and tear.

●Cost Reduction: Lower electricity bills and fewer breakdowns.

🔹 Where are VFDs Used in Facilities Management?

●HVAC systems (fans, blowers, chillers, cooling towers, pumps).

●Pumping systems (water supply, wastewater treatment, irrigation).

●Industrial processes (conveyors, mixers, compressors).

●Elevators & escalators (smooth acceleration/deceleration).

●Data centers (cooling and air handling).

🔹 Working Principle of VFD

●The working principle is based on controlling motor speed by adjusting supply frequency and voltage.

●Motor synchronous speed:

N_s = \frac{120 \times f}{P}

●By reducing frequency, the motor runs slower; by increasing frequency, it runs faster.

●The VFD simultaneously adjusts voltage to maintain motor efficiency and avoid overheating.

🔹 Key Factors of VFD

1. Input supply rating (voltage, phase, frequency).

2. Motor rating compatibility (HP/kW, current).

3. Load type (constant torque, variable torque, constant power).

4. Harmonics control (filters may be required).

5. Control method (scalar V/f control, vector control, or direct torque control).

6. Environmental conditions (temperature, dust, humidity).

🔹 Safety Features of VFD

●Overload protection.

●Short-circuit & overcurrent protection.

●Overvoltage & undervoltage protection.

●Ground fault protection.

●Thermal protection (motor & drive overheating).

●Emergency stop / soft stop.

🔹 Durability of VFD

●Lifespan: 8–12 years on average (can be extend with proper maintenance).

●Capacitors and cooling fans are the most wear-prone parts.

●Dust, heat, and moisture can reduce life if not controlled.

✅ In summary:

A VFD is a smart motor controller that saves energy, improves process control, reduces mechanical stress, and extends equipment life. It is vital in modern facilities management, especially for HVAC, pumps, and automation systems.

Source: LinkedIn Page of Viral Misry

Podcasts

Podcasts